Overview of Upcycling Facility

-

10 acre land with utilization of 9 acre in Phase 1 – Sanand

-

Installed capacity: 8,000 MT/Annum

-

Two stage drying at flakes and granules

-

Effluent Treatment Plant with Zero Liquid Discharge Technology

-

Over 30 % area with landscaping, rain water harvesting and provision for roof top solar

-

Total Hot Washing/Drying Capacity – 14,000 MT/Annum

-

Provision for electric boiler in order to ensure zero emissions

Our Certificates

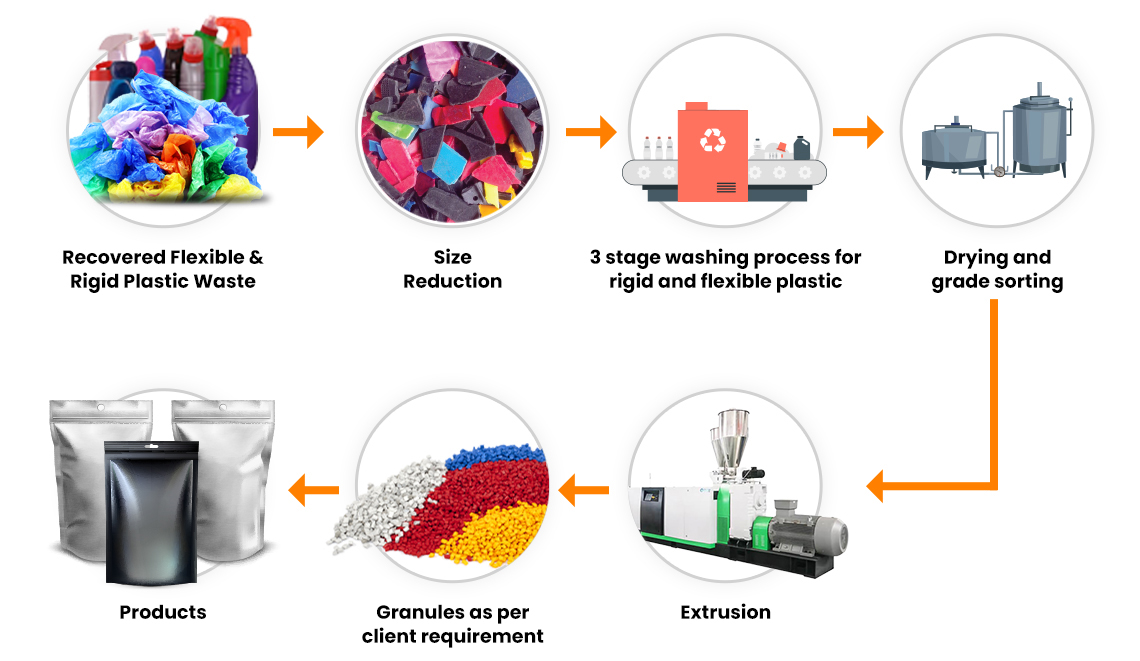

What We Do?

Ensure zero waste to landfill

Laboratory Infrastructure

List of Lab Equipment

-

Injection molding machine with ISO & ASTM standard test specimen molds

-

Spectro-photo meter

-

XRF ROHS testing machine

-

Charpy impact testing machine with different joule scale

-

Melt flow index tester (MFI)

-

Electrical muffle furnace unit

-

Electronic weighing balance with density measuring system

-

ATS 210 moisture analyser

-

HDT / VSP tester. (3-station)

-

Universal testing machine servo (Tensile and Flexural)